- Design Creation:

The first step is creating the design to be printed. This is usually done on a computer using graphic design software.

- Plate Making:

Once the design is ready, it's transferred to the flexible plates. Each color in the design gets its own plate.

- Mounting Plates:

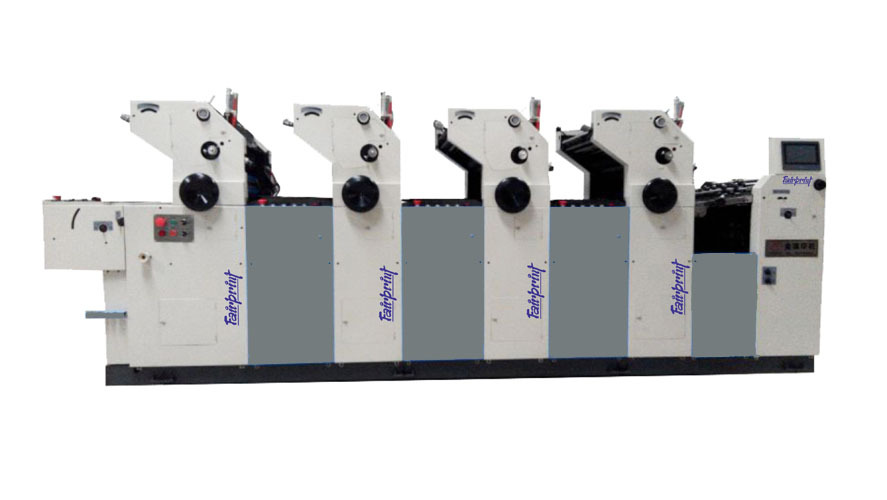

The plates are mounted onto the printing cylinders inside the machine.

- Inking:

The machine applies ink to the plates using rollers. Each plate gets its specific color of ink (cyan, magenta, yellow, or black).

- Printing:

The material to be printed on (like paper or plastic) moves through the machine. The inked plates press against the material, transferring the image.